Each time we think we have found a spectacularly remote monitoring location, an even more inaccessible spot is reported by one of our users. Full-day trips to visit a location have now been beaten by customers who need to charter a plane to reach them. So, remote diagnostics and support are very important.

Read MoreWe are often asked by customers whether AQMesh can operate in cold conditions. Long-term use at temperatures well below freezing, with ice and snowfall, is indeed challenging. Cold weather operation has been key to AQMesh – improved upon and proven in the field – for over 10 years. The main features, described below, have been most recently been put to the test in Iceland.

Read MoreIf you are responsible for air pollution around an oil, gas or industrial site, you have a range of options at different price points. AQMesh offers a cost-effective way to continuously monitor ambient air quality, as frequently as every minute, with readings accessed securely online and user-settable alerts.

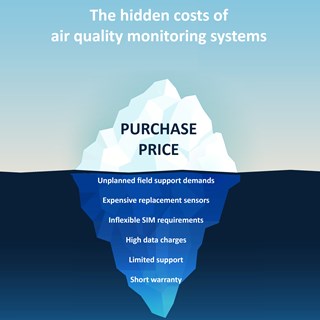

Read MoreAnybody in the market for purchasing a small sensor air pollution monitoring system will need to consider budgets, but it’s not always obvious how the products being reviewed actually compare across their full operational life. A small sensor air quality monitoring system or network can be a significant purchase, so whether project-based or with ongoing monitoring in mind, it is likely that the equipment will be in use for several years. There are six main areas of cost highlighted here, all of which kick in after initial purchase.

Read MoreEveryone loves holidays, whether Christmas or anything else, right? So what’s special about ‘air quality’ people? What we get so excited about are ‘free’ experiments, where distinct changes in activity help to peel away the layers of air pollution measured.

Read MoreGenerally, the limiting factor will be budget. The clue is in the name with hyperlocal air quality monitoring, and pollution levels can vary hugely over short distances. NO measurements around streets, for example, are often significantly different from one side of the road to the other, particularly if there isn’t much wind and/or a street canyon effect.

Read MoreOur hydrogen sulphide (H2S) monitoring journey literally started in the sludge lanes of a UK wastewater treatment plant in 2017. Since then, AQMesh has been used effectively in a range of applications.

Read MoreIf you are considering - or are at the point of buying - a system for local monitoring of air pollution, we have used our decade of experience to offer lists of points to consider. Why more than one list? The critical issues around air quality monitoring vary depending on your project, so we have prioritised points for a range of applications. We hope we have included yours, but please contact us if we can help further.

Read MoreAQMesh is being used for industrial air pollution monitoring around the world because it brings together a range of features and services that have been tailored to the needs of construction, mining, petrochemical and other industrial applications.

Read MoreThere is a major trend towards industrial operators including oil and gas, petrochemicals, construction, mining and transport – rail and ports, as well as roads – wanting to look closely at air pollution on and around their sites.

Read MoreA wide range of industrial operators, including mining, construction, ports, landfill and the oil and gas industry, are looking more closely at the air quality on and around their operational sites. This is increasingly driven by legislation, Environmental, Social and Governance (ESG) ambitions, to establish a baseline, or to understand and manage potential pollution sources.

Read More