Our hydrogen sulphide (H2S) monitoring journey literally started in the sludge lanes of a UK wastewater treatment plant in 2017. Since then, AQMesh has been used effectively in a range of applications.

Monitoring H2S in air at levels of less than one part per billion – well below the level at which the human nose can detect this odorous and harmful gas – AQMesh can be used both to measure very dilute levels and where concentrations are significant. These small ‘pods’, with autonomous power and communications, can be quickly installed around a boundary, providing 24/7 monitoring. Near real-time readings are accessible on a laptop, phone or via alerts, indicating where H2S levels have exceeded a set threshold. This core capability has been used in various sectors.

Waste water, landfill and waste management

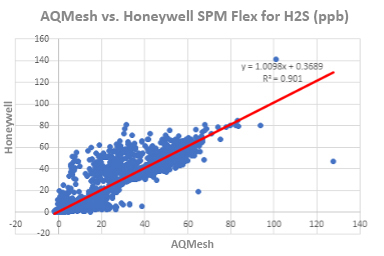

As H2S smells unpleasant – and may be released as a fugitive emission alongside other odorous gases, such as ammonia and mercaptans – AQMesh has been used to monitor air quality at site boundaries. The AQMesh team cooperated with a UK water utility in 2017 to prove the accuracy of the AQMesh sensor against a Honeywell SPM Flex, showing very good correlation.

As H2S smells unpleasant – and may be released as a fugitive emission alongside other odorous gases, such as ammonia and mercaptans – AQMesh has been used to monitor air quality at site boundaries. The AQMesh team cooperated with a UK water utility in 2017 to prove the accuracy of the AQMesh sensor against a Honeywell SPM Flex, showing very good correlation.

During the monitoring period the AQMesh pods were moved from an outdoor monitoring location to indoor, and this saw a significant uplift in H2S levels. Across this range (0 to over 100ppb) the correlation with the Honeywell unit was very strong, at an R2 of around 0.9.

Since this original study, AQMesh has been used to monitor at landfill and waste management sites around the world, including New Zealand, Iceland, South Africa and UK. Continuous, real-time boundary measurements can be used to investigate odour nuisance complaints, with alerts set up if concentrations exceed agreed limits, over a user-set time interval. As pods are deployed closer to the source of emissions, monitoring can be used to alert operators to high levels of H2S, as well as other pollutants. Action may need to be taken, such as enclosing spaces or protecting staff from inhaling elevated levels of pollutants.

Industrial processes

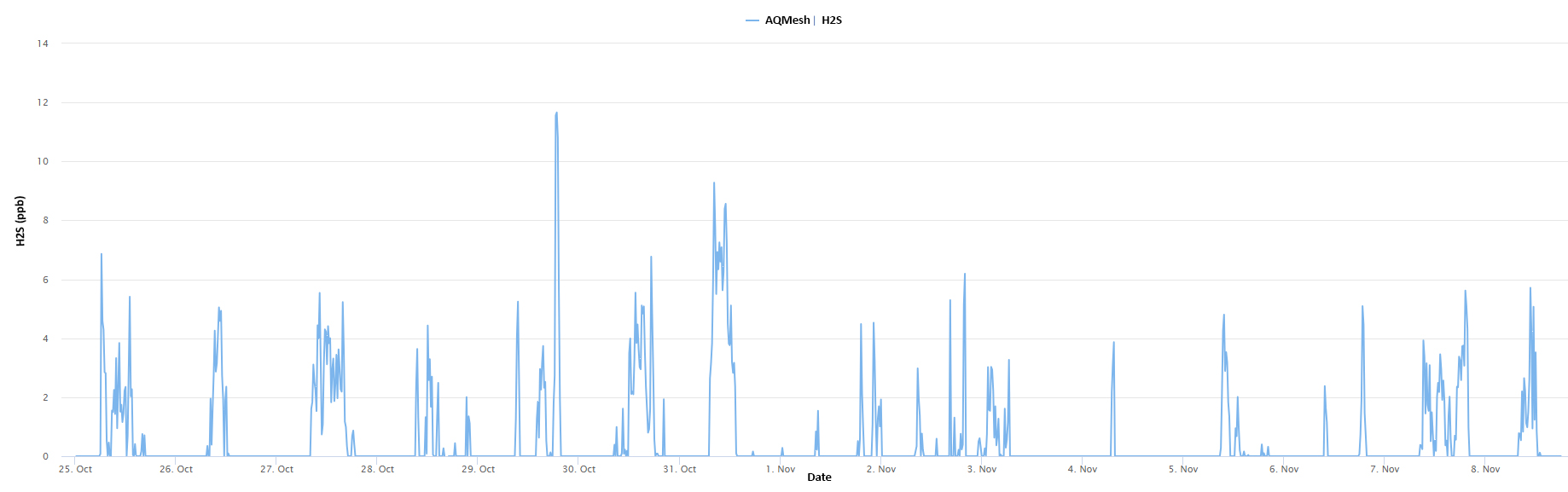

Linked to H2S from waste, AQMesh is currently being used to monitor H2S levels at a site close to a biorefinery plant, where measured levels of the gas show regular peaks.

Other industrial processes where real-time H2S monitoring can add value are the oil and gas industry – particularly relating to sour, or sulphur-heavy gas, and oil sand extraction – as well as lime manufacture and paper processing. The most common air pollutants generated by the pulp and paper industry are nitrogen oxides, sulphur compounds, particulate matter (PM) and volatile organic compounds (VOCs), all of which can be monitored by a single AQMesh pod. AQMesh has been used in all these applications, providing secure, confidential, real-time information to operators, to protect staff and neighbouring communities, and identify sources, mitigating where necessary.

Ports and shipping

Shipping has long been under fire regarding the levels of sulphur in fuel, as well as other air pollutants. AQMesh has been used in various studies which have aimed to identify the sources of pollution around ports, as harbourside operations and nearby traffic movements – inside the port and on roads in the neighbouring area – also create air pollution. Capturing plumes from ships is notoriously difficult but possible, using AQMesh capturing data at 1-minute intervals and wind speed and direction (an integrated AQMesh option), analysed to identify the direction and scale of the source.

Volcanic activity

Volcanoes present another significant source of sulphurous emissions. Five AQMesh pods were installed at and near Keflavik airport in Iceland, monitoring gases produced by the nearby volcano at Fagradalsfjall, including H2S, sulphur dioxide (SO2) and nitrogen dioxide (NO2). The monitoring project was a collaboration between the airport authority, Isavia, and the Icelandic Environment Agency, to ensure good air quality for Isavia staff as well as users of the airport and local residents. Three AQMesh pods were located at Keflavik airport, with two others installed in nearby towns to monitor air quality in the local community, with measurements published on a website.

A 2017 study in Nicaragua, led by the University of Leeds, predated the AQMesh H2S sensor option, focusing on SO2 and particulate matter. The pods, with independent power and communication, were set up to understand how it might be possible to provide early warning to residents of dangerous levels of SO2 and PM.

Monitoring hydrogen sulphides to prevent short-circuits at data centres

H2S in the air - which can come from a number of sources - is a particular risk to information technology, as it can damage copper circuitry. Airborne H2S and SO2 can form a weak acid, which can cause dendrites to form on electronic components, resulting in short-circuits and potential data loss. This risk is growing worldwide, with more compact circuitry increasing the risk of short-circuits, and more data centres being located in areas with higher levels of H2S and SO2 in the air.

H2S attacks copper, forming thin films of metallic sulphides - dendrite whiskers - which speed up corrosion, so some data centre operators monitor H2S outdoors, near air intakes, and internally within UPS rooms to avoid sulphur-induced degradation in power modules. These gaseous contaminants can lead to deterioration of silver solder as well as copper surfaces on computer circuit boards, leading to intermittent and hard errors, caused by either impeding the flow of electricity or forming unintended circuit paths.

Data centres focus on filtration for particles and management of temperature and humidity, but gases in the air may bypass such filtration systems. One method of monitoring for potential corrosion is to expose silver and copper coupons to the air in the server centre and measure corrosion over a month. This is an effective methodology, but the results of the month-long test may arrive too late to prevent damage. Monitoring of the air coming into the building allows real-time notification of elevated levels of H2S and SO2, allowing action to be taken before polluted air enters the data centre.

For more information about how AQMesh can help with H2S monitoring contact our experienced team today and we will be happy to discuss your project.